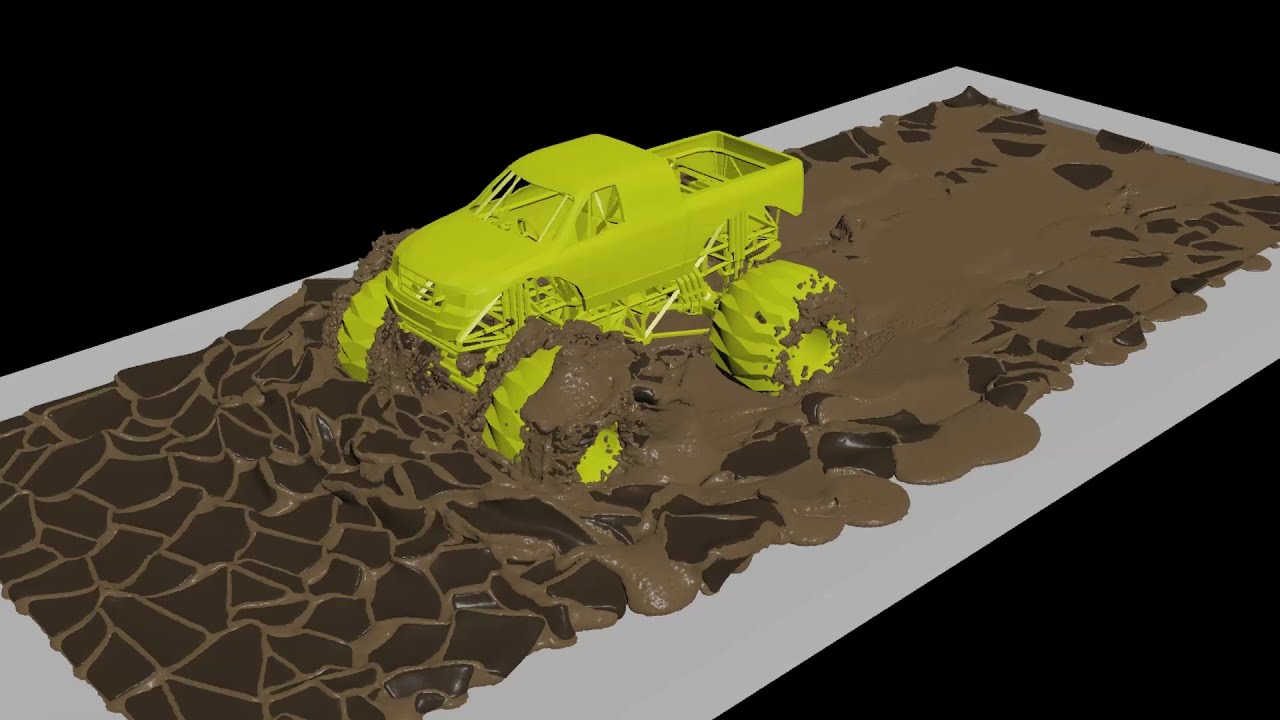

If drawn on a chart with viscosity on a vertical axis and the temperature on a horizontal axis, the slope would be more horizontal with higher viscosity indexes. A higher number means the lubricant changes viscosity at a lower rate based on the temperature. Highly refined mineral oils have a VI of approximately 120. While the VI has no units of measure, it is well known that the viscosity index of a conventional mineral oil is between 95 to 100. This is then compared to a scale based on two reference oils. To determine an oil’s VI, the viscosity is measured at two temperatures: 40 degrees C and 100 degrees C. Understanding VI is important to discern whether the lubricant in question meets the asset’s requirements based on the operating temperature range. The change in an oil’s viscosity due to a temperature change is called the viscosity index (VI). The lubricant’s formulation and quality will impact how much its viscosity will drop with an increase in temperature. Viscosity is also affected by temperature. Taking a proactive approach to monitoring your lubricant’s viscosity can make a big difference in the health and life of your machinery. It is influenced by several factors such as contamination with water, particles or other lubricants. Viscosity can be defined as an oil’s resistance to flow and shear. Up the viscosity solver and is sufficient accuracy for most simulations.A lubricant’s viscosity is its most important property. Object can be a good way to preview viscosityĬhoosing Float 32-bit for the precision on the Viscosity tab will speed Turning off Reseeding should alleviate this problem. Particles newly introduced by the reseeding process can be apparent. When surfacing very slow moving viscous particles, occasionally Metaballs might provide better results than Average Positionįor surfacing goopy, viscous fluids with the Particle Fluid Surface Viscous sim might need more substeps than the 1 that the FLIP Solver

Will be more accurate with smaller substeps. While the viscosity solver should always be stable, it The FLIP Solver computes the number of substeps to calculate based Scale to about 1.4 should alleviate this problem. Object to >= sqrt(3) or decreasing the Grid Increasing the Particle Radius Scale on the FLIP Particles might freeze in air if they are too small to be resolved However, if your sim is only slightly viscous, individual flying Particles method to No Detection turns off this behavior and Viscous liquids it can lead to particles creeping off the surfaceĮven with very high viscosity. This works well for fluid with no viscosity, but for The FLIP Solver will detect particles that are leaving the surfaceĪnd are too small to be resolved on the grid and treat themīallistically. If Under-Resolved Particles is set to Treat as Ballistic,

Input to the FLIP Solver, you can arbitrarily edit the viscosity If you override the Viscosity field through the Volume Velocity The default attribute name is viscosity but you can change it as well scaling the value and controlling how the value of the attribute affects existing viscosity values using the other parameters on the Viscosity sub-tab. In the FLIP Solver node parameters, click the Volume Motion ▸ Viscosity sub-tab, then turn on Enable Viscosity and Viscosity by attribute. You can use a per-particle viscosity attribute to control a varying viscosity field. This tool does the above steps on the selected particle fluid object automatically, and sets the initial value of the Viscosity parameter of the object based on the object’s scale. Use the Make Viscous tool on the Particle Fluids shelf tab. Then in the FLIP object parameters, click the Physical tab and set the Viscosity. In the FLIP Solver node parameters, click the Volume Motion ▸ Viscosity sub-tab, then turn on Enable Viscosity. Set the uniform viscosity of a FLIP fluid object At the default scale, you will need values around 1000 for a thick fluid, and around 10000 for a doughy fluid. The value of the Viscosity parameter depends on the scale of the particles.

0 kommentar(er)

0 kommentar(er)